The dry powder fire extinguishing system is one of the main equipment for fire extinguishing systems in petrochemical, oil tankers, oil depots, gas stations, ports, airports, hangars, and other engineering projects. The dry powder fire extinguishing system is powered by nitrogen gas, which provides pressure to the dry powder tank and pushes the dry powder extinguishing agent inside the tank. It is transported through pipelines to the dry powder gun, or fixed nozzle for spraying, in order to extinguish flammable and combustible liquids, gases, and electrical equipment fires.

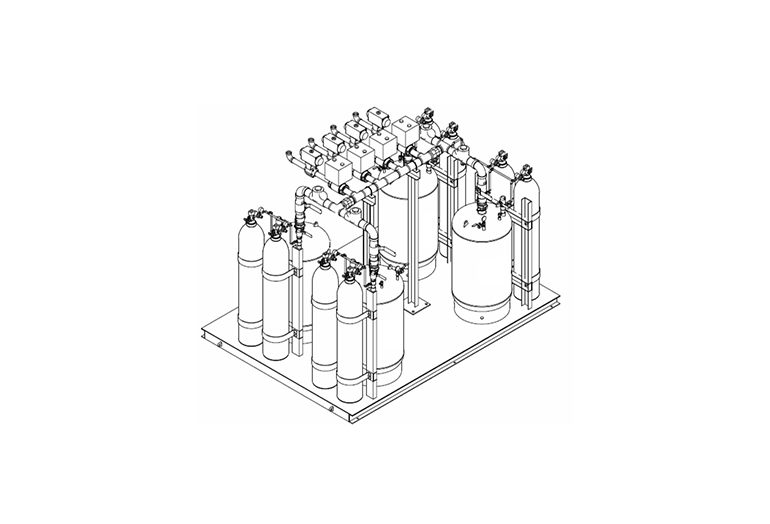

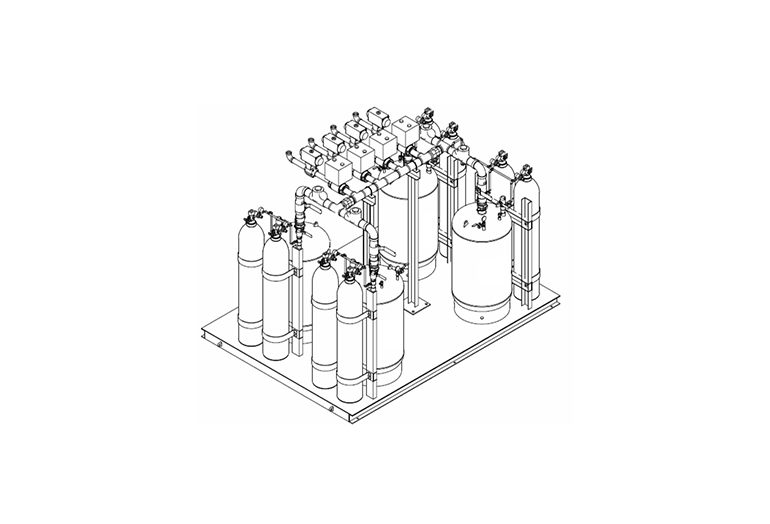

The dry powder fire extinguishing system consists of a starting device (such as a starting cylinder+pull rod mechanism), a nitrogen cylinder group, a pressure reducing valve, a dry powder tank, a dry powder gun, a dry powder gun, a dry powder nozzle, an electric control cabinet, valves, and piping components. Generally, the automatic fire detection system is linked with the dry powder fire extinguishing system.

The dry powder fire extinguishing system can be used for Class A, B, C, and D fires, and a large number of them are still used for Class B and C fires (corresponding dry powder fire extinguishing agents should be selected according to the protected object). Its main characteristics are as follows: short fire extinguishing time, high fire extinguishing efficiency, and particularly significant fire extinguishing effect on petroleum products; Good insulation, capable of extinguishing fires on live equipment, with minimal damage to equipment after extinguishing; Cold areas do not require antifreeze and can be used in water scarce areas; Dry powder fire extinguishing agents do not deteriorate after long-term storage.

The working principle of the system is to use the high-pressure nitrogen in the nitrogen cylinder group to be depressurized by the pressure reducing valve, allowing the nitrogen to enter the dry powder tank. Part of it is sent to the bottom of the tank to act as a loose dry powder extinguishing agent. As the pressure inside the tank increases, some of the dry powder extinguishing agent enters the powder outlet pipe with nitrogen and is sent to the outlet valve of the dry powder gun or dry powder fixed nozzle. When the pressure at the outlet valve of the dry powder gun, gun or dry powder fixed nozzle reaches a certain value (when the pressure gauge value on the dry powder tank reaches 1.5~1.6MPa), the valve is opened (or the constant pressure blasting diaphragm automatically bursts), and the pressure energy is quickly converted into velocity energy, This high-speed gas powder flow is sprayed from the nozzle of the dry powder gun (or dry powder gun, fixed nozzle), directed towards the fire source, cutting the flame, breaking the combustion chain, and playing a role in quickly extinguishing or suppressing the fire.